Toughenable Enamelled Glass

History

For thousands of years glass has been a means of decoration. Coloured glass was used as long ago as 6000 BC by ancient Egyptians in their jewellery, an increasing range of tints allowed an extra creativity in blown glassware, stained glass in windows brought deep colours into buildings, patterns pressed onto the glass surface mixed transparency and shadow - the vibrance and versatility of glass have helped to make it a vital ingredient of commercial and interior design.

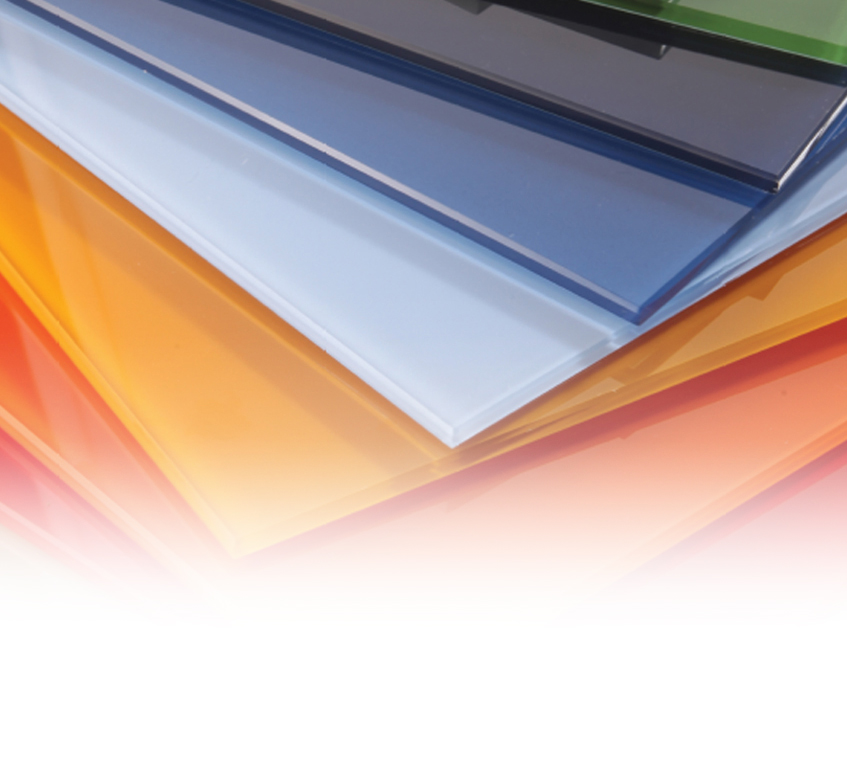

Toughenable enamelled glass from an industrial leader

Ghazvin Glass has established a reputation for offering high quality flat glass products, clear and tinted, and has now introduced a new addition to its product range - Vinamel t - a toughenable enamelled glass.

changing our view of the world

changing our view of the world

- a palette of bright, dense colours

- high reflection of light, controlled by design and location

- addition of patterns extend the options from transparent to completely opaque

- modern look and feel

- ability to give an enlarged space effect

- surfaces resistant to temperature and humidity

- scratch resistance

- ease of installation, as construction or retrofitting

NOW

Temperable Enamelled

Cutting

Grinding

Tempering

BEFORE

Base Glass

Cutting

Grinding

Enamelling

Tempering

Vinamel t fact sheet

Vinamel t fact sheet

- various colours and thickness from 6 to 10mm

- with a range of patterns, or incorporating designs to order

- available as a single sheet or laminated

- standard sizes 3210 x 2250 mm and 2500 x 1605 mm, or cut to order

- drilled holes, cut-outs, and other features also available

Toughenable Enamelled Patterned Glass

Toughenable Enamelled Patterned Glass

An advantage of coloured glass sheets is that they give people visual calmness and thus reduce environmental stress. Nowadays, in addition to traditional patterns, modern silkscreened glass is being produced in new designs (mono-color or multi-color) for various purposes. One novel approach is to print the customer's own design (created by architects, designers andartists) on a glass sheet of a particular thickness and size, based on the customer's taste and the application. The product can be used for internal space partitioning, artificial walls and the like. The most outstanding features of GGC Silkscreened Float Glass are its capability to be cut and beveled and its tolerance of any kind of secondary processing procedure.

Quality Control

Ghazvin Glass carries out a series of tests on the toughen-able enamelled glass to ensure that it is fit for purpose:

- Acid test

- Alkali test

- Abrasion resistance test

- Gloss test

- Enamel coverage test

- Colour range test

Each test measures the glass for repeatability of values within a predetermined range.

Ghazvin Glass understands the relevance of having the same values for glass from the beginning of production this week to that manufactured some weeks (or even years) ago.

Vinamel t application in design and architecture

Glass has long been an important building material, thanks to a combination of its physical properties and the opportunities it offers to designers and architects, engineers and artists, to bring light and reflection to their work. For over 50 years Ghazvin Glass has responded to the market needs for patterned surfaces and printed designs, but this new product is a major step forward.

Thanks to properties of Vinamel t’s decorative range, chiaroscuro features, scratch resistance and strength, toughen-able enamelled glass is suitable for many applications. Such features in addition to durability, cost and energy saving, security, hygiene, distinctiveness, practicality, and last but not least transparency makes Vinamel t instantly suitable for various application such as:

Interior design

Interior design aims to achieve a desired feel within a closed space by coordinating the construction materials, dimensions and colours, with furniture and fittings. Like other art forms, interior design today often seeks to combine traditional and modern styles. Thanks to its decorative range, chiaroscuro features, scratch resistance and strength, toughenable enamelled glass is suitable for many applications in interior design.

Public and commercial buildings

The first noticeable feature of a building is the design of its facade. Providing many ways to design a pleasing exterior in a durable material means that toughenable enamel glass is a welcome addition to building materials, with the added benefits of security, energy management and cost savings.

Public spaces

Materials used in public spaces are expected to be practical, easy to clean, and attractive. Enamelled glass meets these expectations for applications as walls, floors, partitions, doors, ceilings, etc. Where necessary, the enamelled glass can be used to give a distinctive design to the space (for example, bright red for the fire department, green for the clinic, blue for the police station) or to harmonise the space with its surroundings.

Offices

Employees and also visitors to offices and other public spaces are better motivated by the combination of natural light and a peaceful design, thanks to the two glass properties of transparency and reflection. In addition, the use of toughenable enamelled glass can also provide a safe and secure working environment.

Clinics and hospitals

In areas where hygiene is important (clinics, surgeries, schools, clean rooms, etc) the glass surface (and the cooked enamel) is flat and therefore easy to clean and to disinfect.

Religious places

People in prayer connect visually to their surroundings, forming a strong bond of inner spirit and space. The architectural design and the materials used play an important role.

Art and culture centres, sports facilities, hospitality spaces

Design of spaces such as cinemas, theatres, university colleges, community centres, sports facilities, and hospitality spaces, is important in attracting people and holding their interest. A wide range of colours and patterns is critical to successful design.

Residential buildings

Enamelled glass enables designers to benefit from the ease of installation with slim panels when working within confined spaces, and the excellent light reflection compares well with products such as tiles and ceramics. Also, the ability to tailor design to personal taste adds endless opportunities to please consumers.

Technical Information

|

Processing Possibilities |

Comments |

||

|

Safety |

Toughened |

Convection tempering furnace is highly recommended. The enamelled side must be facing upwards. |

|

|

Laminated |

Laminating via PVB, or EVA films |

||

|

Cutting |

Rectangular or circular |

Easily cuttable before tempering. |

|

|

Shaping and edge finishing |

Edge grinding |

Edge grinding should be prosseced before tempering. - enamelled side always facing downwards. |

|

|

Drilling |

Edge grinding should be prosseced before tempering. - enamelled side always facing downwards. |

||

|

Notches |

Always before tempering. |

||

|

Special treatments |

Sand-blasting |

Sand-blasting could be done on both sides before or after tempering. |

|

|

Acid-frosting |

Acid etching is available on both sides before or after tempering. (both soft etching & deep etching) |

||

|

Printing |

Any printing is applicable. |

||

|

Bending |

Enamelled side always facing away from the mold. |

||

Other Acpects

|

Other Acpects |

||

|

Enamelled viscosity on glass |

Full |

Enamel is partially cooked before application. |

|

Humidity resistant |

Yes |

All Vinamel t colours could be used in wet and humid spaces such as kitchen or bathroom. Note: The direct temperature or water infiltration is not recommended. |

|

Indirect temperature resistant |

Yes |

Once tempered. |

|

UV resistant |

Yes |

Consistant colour even with direct UV ray. |

The average throughput IR thermal radiation of the sun

(6mm Glass)

|

Wave length |

IR transmittance ( C Series ) |

IR transmittance ( V Series ) |

|

750 |

2/84 |

2/44 |

|

770 |

2/84 |

2/44 |

|

790 |

2/86 |

2/46 |

|

800 |

2/86 |

2/46 |

|

820 |

2/86 |

2/46 |

|

840 |

2/86 |

2/46 |

|

860 |

2/87 |

2/47 |

|

880 |

2/91 |

2/51 |

|

900 |

2/91 |

2/41 |

|

920 |

2/94 |

2/44 |

|

940 |

2/96 |

2/46 |

|

960 |

2/97 |

2/47 |

|

980 |

2/98 |

2/48 |

The average throughput UV rays of the sun

(6mm Glass)

|

Wave length |

UV transmittance |

Notes |

|

100 |

- |

This is clear that avery high percentage of UV rays within the UVA wavelength of 320 to 420 nanometer is absorbed and therefore not transmitted through |

|

120 |

- |

|

|

140 |

- |

|

|

360 |

2/2 |

|

|

380 |

2/2 |

|

|

400 |

2/23 |

|

|

420 |

2/25 |